Definition of torque: vertical force * distance from the center of rotation

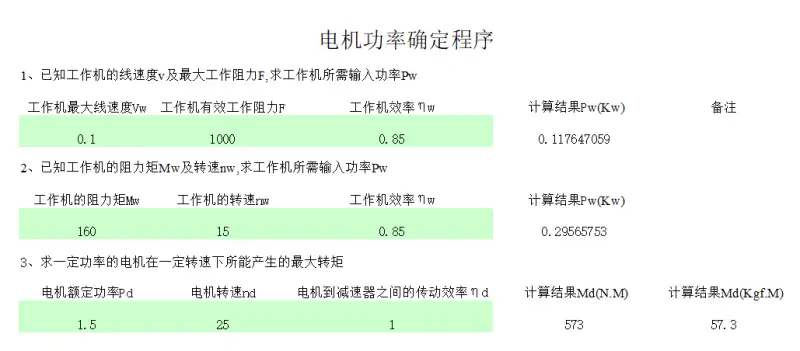

1. The motor has a common formula:

P = M * N / 9550

P is the power, M is the motor torque (also called torque), N is the motor speed, when M and N are rated values, the motor power is also rated power, rated refers to the limit value of the motor can work

2. Transient torque refers to the transient value of the motor when the load changes and the speed changes, and has nothing to do with the rating. Specifically, this value can exceed the rated torque. If the motor speed is rated at this time, the motor may be overloaded. This overload can only last a short time, this time depends on the motor design.

3. The power of the inverter is generally greater than or equal to the three-phase asynchronous motor, but this is not enough. The rated current and overload current of the inverter must be greater than or equal to the rated or maximum value required by the motor to ensure that the motor can output Sufficient torque (rated and transient torque), otherwise the inverter may not drive the motor and load.

Stepper motor is an electromagnetic actuator that can convert digital input pulse into rotary or linear incremental motion. Each time a pulse motor input shaft step is incremented by one step angle. The total rotation angle of the motor is proportional to the number of input pulses, and the corresponding speed depends on the input pulse frequency.

Stepper motors are one of the key components in mechatronics products and are usually used for positioning control and constant speed control. The stepper motor has low inertia, high positioning accuracy, no cumulative error, and simple control. Widely used in electromechanical integration products, such as: CNC machine tools, packaging machinery, computer peripherals, copiers, fax machines, etc.

When choosing a stepper motor, first ensure that the output power of the stepper motor is greater than the power required by the load. When choosing a power stepper motor, the load torque of the mechanical system must be calculated first. The torque frequency characteristics of the motor meet the mechanical load and have a certain margin to ensure its reliable operation. In the actual working process, the load torque at various frequencies must be within the range of the torque-frequency characteristic curve. Generally speaking, a motor with a large maximum static torque Mjmax has a large load torque.

When choosing a stepper motor, the step angle should be matched with the mechanical system, so that the pulse equivalent required by the machine tool can be obtained. In order to make the pulse equivalent smaller in the mechanical transmission process, one can change the lead of the screw, and the other can be completed by the subdivision drive of the stepper motor. But subdivision can only change its resolution, not its accuracy. Accuracy is determined by the inherent characteristics of the motor.

When choosing a power stepper motor, the load inertia of the mechanical load and the starting frequency required by the machine tool should be estimated to match the inertial frequency characteristics of the stepper motor with a certain margin, so that the highest continuous working frequency can meet the machine tool. Need to move fast.