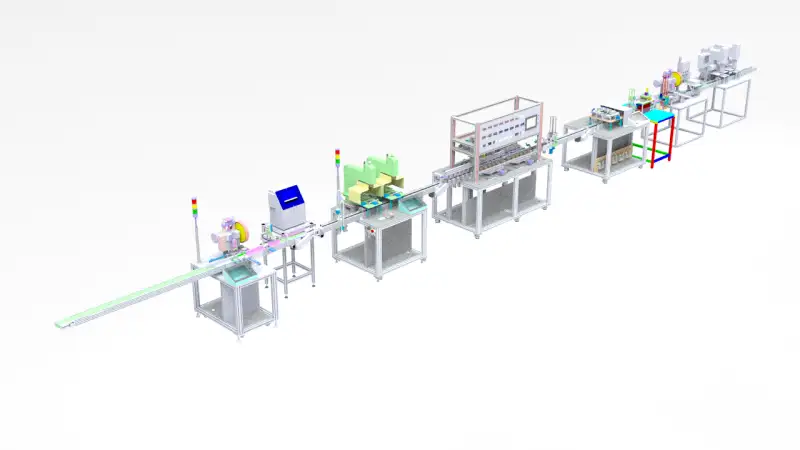

Dynamic automatic weight checking scales have become an essential component in various industries that involve the packaging and processing of products. These advanced weighing systems provide accurate, efficient, and reliable weight measurements, leading to improved productivity and quality assurance. Incorporated with advanced technology, these scales offer a high level of automation, enabling them to quickly…