The chain plate conveyor is a commonly used device for material transportation in industrial production, and its design and selection directly impact the performance and stability of the equipment. This article delves into the design rules of the chain plate conveyor, including the selection of chain plates, chain wheels, and other crucial aspects, aiming to provide valuable guidance for engineers and designers.

- Introduction

The chain plate conveyor is a device used to transport materials along a chain, widely applied in manufacturing, mining, and other fields. When designing a chain plate conveyor, various factors need to be considered to ensure the efficient operation and long-term stability of the equipment. This article explores key points related to design rules.

- Design Rules

2.1 Load Calculation In designing a chain plate conveyor, the primary consideration is the weight of the materials to be carried. Accurate load calculations determine the dimensions and strength of components such as chain plates and chain wheels, influencing the overall performance of the conveyor.

2.2 Conveyor Speed Conveyor speed is another crucial design parameter directly affecting production efficiency. Designers need to determine the appropriate conveying speed based on actual production needs and ensure that the design of chain plates and chain wheels can meet this requirement.

2.3 Distance and Height The conveying distance and height of the conveyor are also critical design factors. This involves the overall structural design of the conveyor, including the design of support structures and the drive system.

2.4 Environmental Factors The working environment also plays a significant role in the design of the chain plate conveyor. If the environment is harsh, such as high temperatures or high dust levels, designers need to choose materials for chain plates and chain wheels that are resistant to high temperatures and dust, ensuring the stable operation of the equipment.

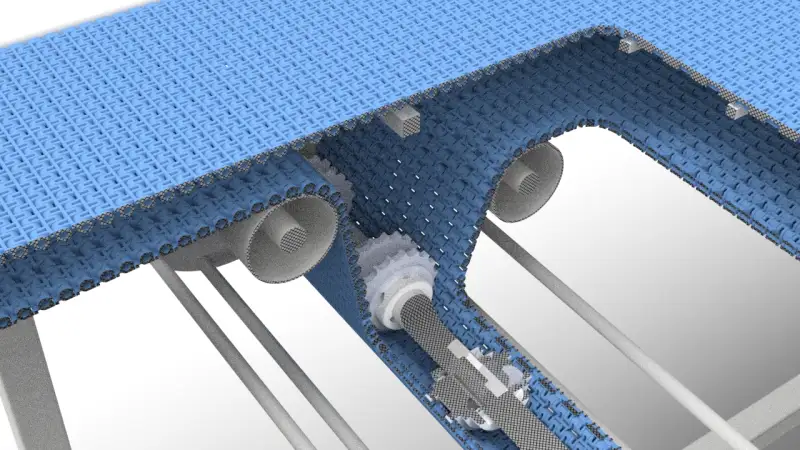

- Selection of Chain Plates

3.1 Material Selection The choice of material for chain plates directly affects their strength and wear resistance. Common materials for chain plates include carbon steel, alloy steel, stainless steel, etc. Designers need to select the appropriate material based on the actual working environment and material characteristics.

3.2 Strength Calculation The strength of chain plates needs to meet the requirements of carrying materials. Designers need to perform strength calculations to ensure that chain plates do not break or deform during operation.

3.3 Plate Shape The design of the chain plate shape directly affects the efficiency of material conveyance. Designers need to consider the characteristics of the materials and choose the appropriate chain plate shape to reduce resistance during material conveyance, thereby improving conveying efficiency.

- Selection of Chain Wheels

4.1 Material Selection The choice of material for chain wheels is equally important and should possess sufficient strength and wear resistance. Common materials for chain wheels include alloy steel, cast iron, etc. Designers need to choose matching materials for chain wheels based on the material of the chain plates and the working environment.

4.2 Gear Parameters The gear parameters of chain wheels directly affect the transmission ratio and driving efficiency of the conveyor. Designers need to choose reasonable gear parameters, such as module and number of teeth, to ensure the smooth operation of the transmission system.

4.3 Installation Method The installation method of chain wheels is also a factor to consider in the design. Different installation methods can affect the arrangement of chain plates and the transmission effect of chain wheels. Designers need to choose a suitable installation method based on specific circumstances.

Designing a chain plate conveyor is a complex and crucial engineering task that requires consideration of multiple factors. This article summarizes key points of design rules, including load calculation, conveyor speed, distance and height, and environmental factors. In the selection of chain plates and chain wheels, it involves material selection, strength calculation, plate shape design, gear parameters, installation methods, and more. When designing a chain plate conveyor, designers should comprehensively consider these points to ensure that the final design meets actual production needs, ensuring the efficient operation and long-term stability of the equipment.