Recently, masks have become extremely popular, which has caused a serious shortage of masks. The mask machine has also received much attention. Now I will share the drawings of the production process of the mask machine with a simple technique and dedicate it to friends in need. I hope it will be helpful to everyone.

1.Mask making process

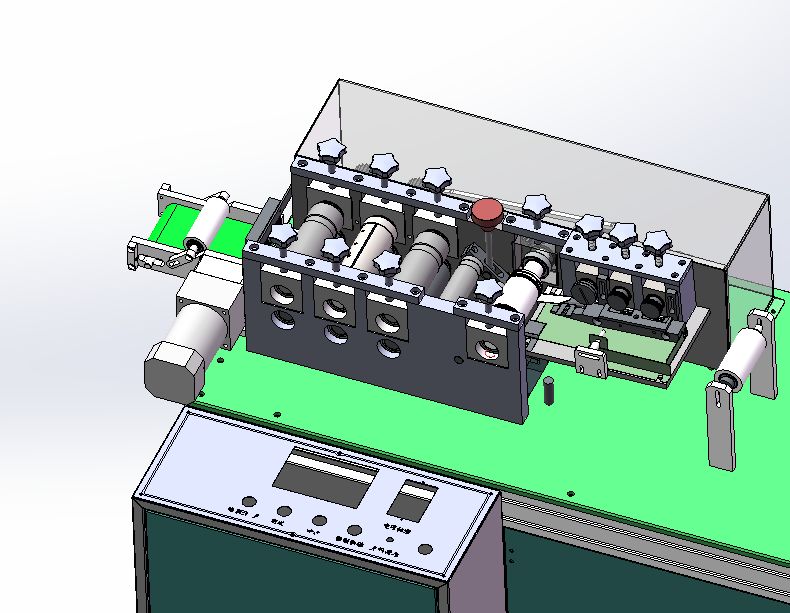

1.1 Raw material feeding process

1.2 Cloth rack

2.Mask treatment process

2. Institutional analysis in the process

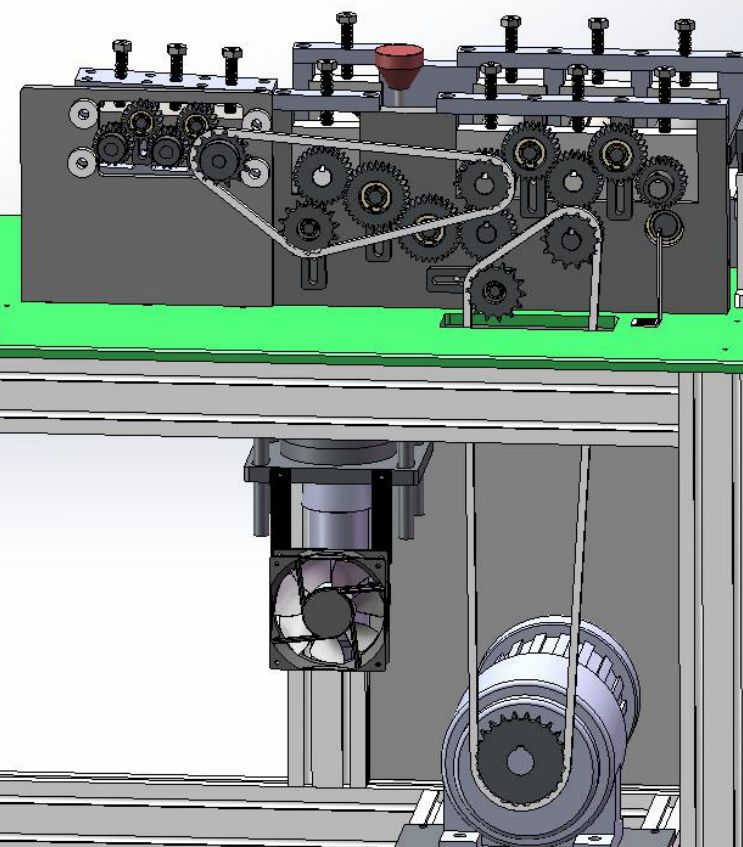

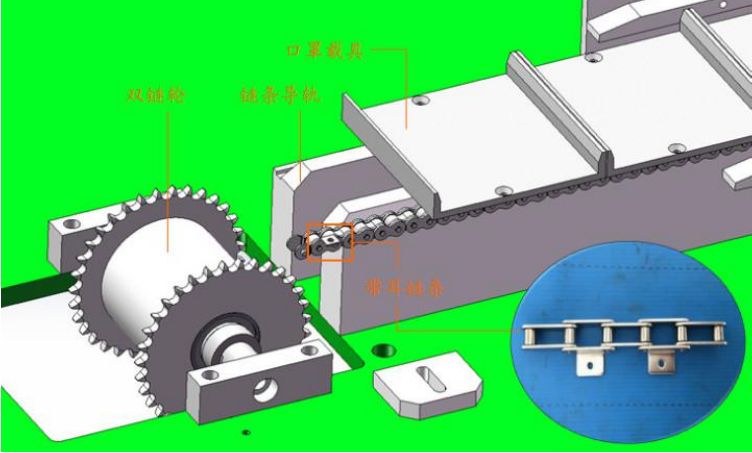

2.1 The whole process, except for the separation of the conveyor belt, there is only one drive motor, and the power of each moving drum is

From this motor, the intermediate power is transmitted through sprocket chains, gears and other transmission mechanisms.

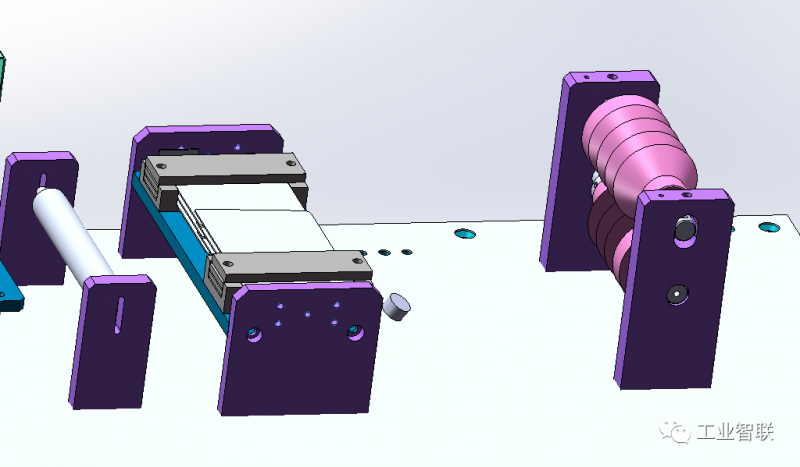

2.2 Cutting process of fold nose bridge

Wrinkle forming should pay attention to the horizontal alignment of the cloth placing rack and the double-blade rotary cutting. It is easy to cause problems such as the wrinkle is not in the center and the feed is off-center. Flanged, see the following figure:

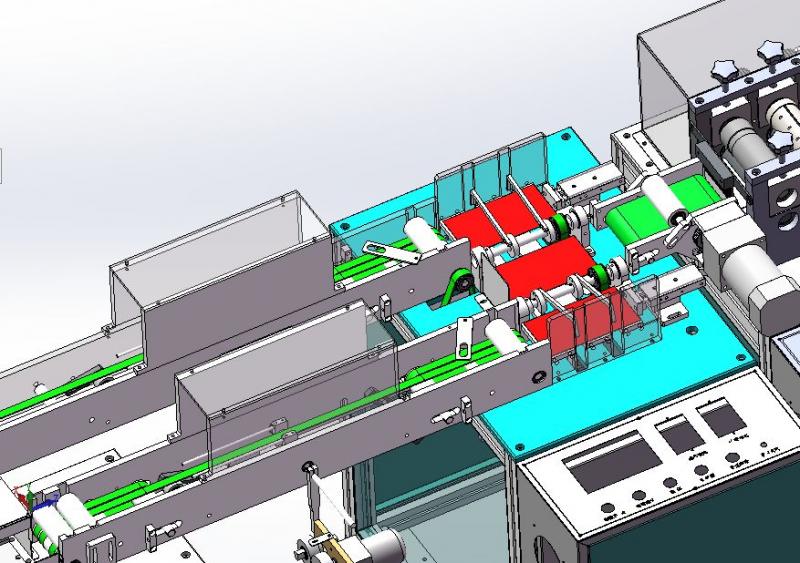

3.Main material distribution process

3.1 Material distribution mechanism

Because the previous process is more efficient, in order to match the production speed, a drag-and-drop method is used, and this process is used to distribute the mask body from the previous process.

The three red ones in the picture are the mask main body. The previous process sent the mask main body to the middle position, and then the mask main bodies were sequentially dialed into the left and right sides by the levers on both sides. Push into the conveyor.

4. Ear strap welding / folding

Because the earband welding / folding process -1 and -2 are the same, only one is analyzed here.

First, the work order

1. The main body of the mask is transported from the previous process to the feeding place, and follows the stepping conveyor line;

2. Weld the earband to the mask body through the earband welding mechanism;

3. Fold the earband inward through the earband folding mechanism; (this mechanism is what I mentioned earlier,

A lot of ears)

4. The finished masks enter the palletizing mechanism, and then each 10 pallets are placed on the unloading conveyor belt and removed by hand.

Institutional analysis

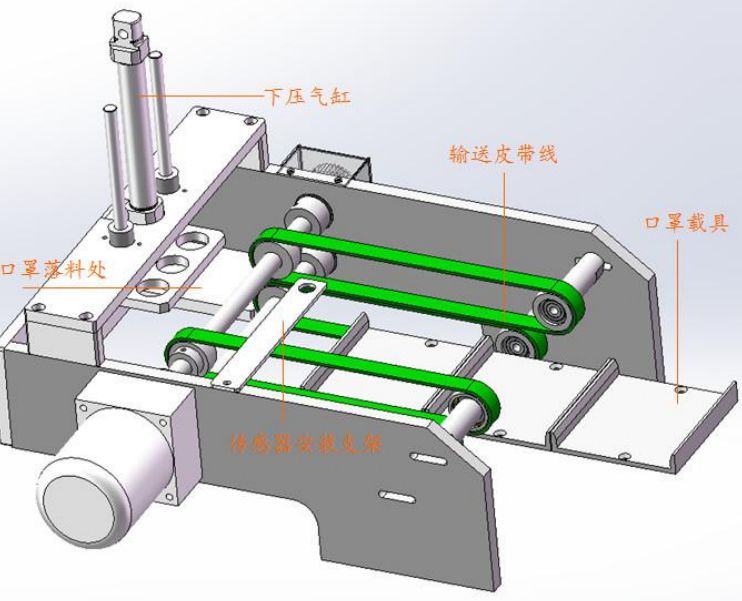

1.Stepping conveyor line

In fact, the conveying line is very common, mainly to talk about the way it fixes the carrier:

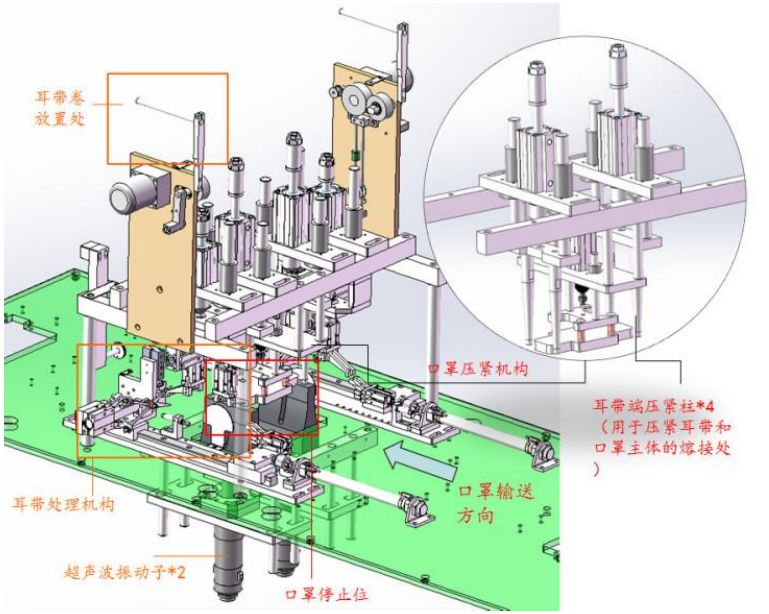

2.Earband welding mechanism

1) First talk about the specific sequence of action of this mechanism

Conveyor line conveys mask body to mask stop position

→ Earband processing mechanism, place earbands on both ends of the mask;

→ The pressing mechanism is pressed down;

→ The ultrasonic welding machine works, and the earband is welded to the mask;

→ Done.

2) Ordinary, talk about institutions worth mentioning

It is estimated that this organization is most interested in how the earband is intercepted and put on the mask.Firstly

A moment, the earband processing mechanisms on the left and right sides of the mask are symmetrical, so the principle is the same.

See the detailed picture below:

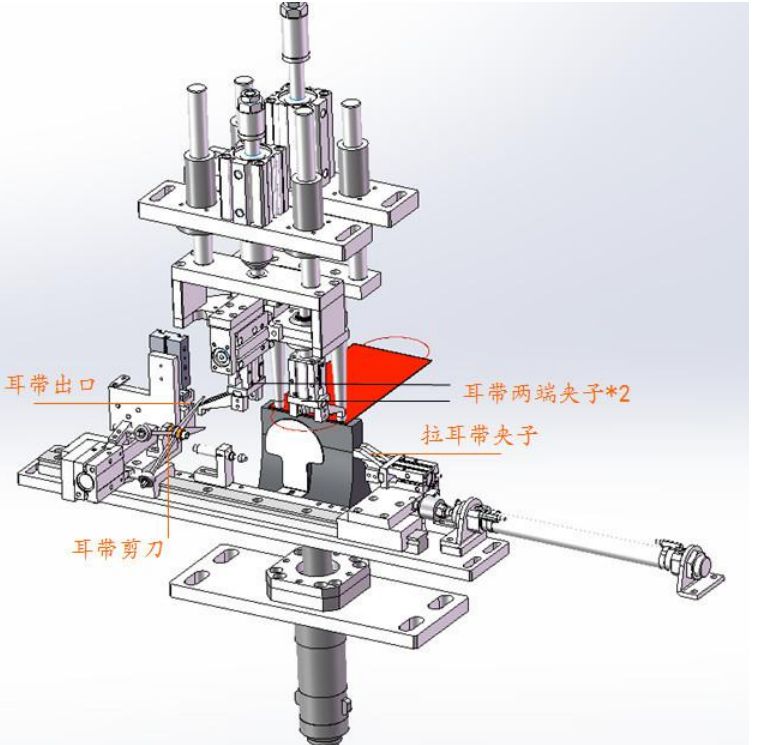

→ After the earband is rolled down from the upper earband, it comes out from the earband exit;

→ The right-most pen-shaped cylinder drives the ear strap clip, grips the ear strap out;

→ Clip on both ends of the earband to clamp the earband;

→ Scissors cut the earband, and the clips at both ends of the earband place the ends of the earband in place;

→ Perform welding operation;

→ Repeat the above operation.

The above is the entire operation flow of the earband processing mechanism. Let’s take a look at the specific mechanism of the clips at both ends of the earband:

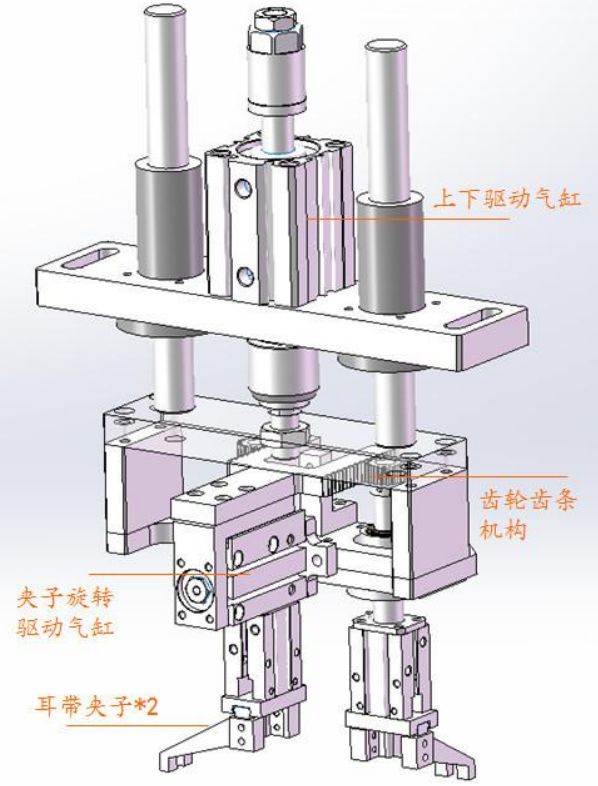

When rotating, the upper and lower cylinders are lifted; when in place, the upper and lower cylinders are lowered.The clamp rotates and drives the cylinder, and the linear motion is converted into rotary motion by driving the rack and pinion mechanism (the structure of this part is slightly different in each generation model, the specific details can be downloaded in the public account to view).

Note: The two clips in the picture only show two different states, which are symmetrical in actual use.

Let’s take a look at the details of the earband scissors and the earband clip:

3.Earband folding mechanism

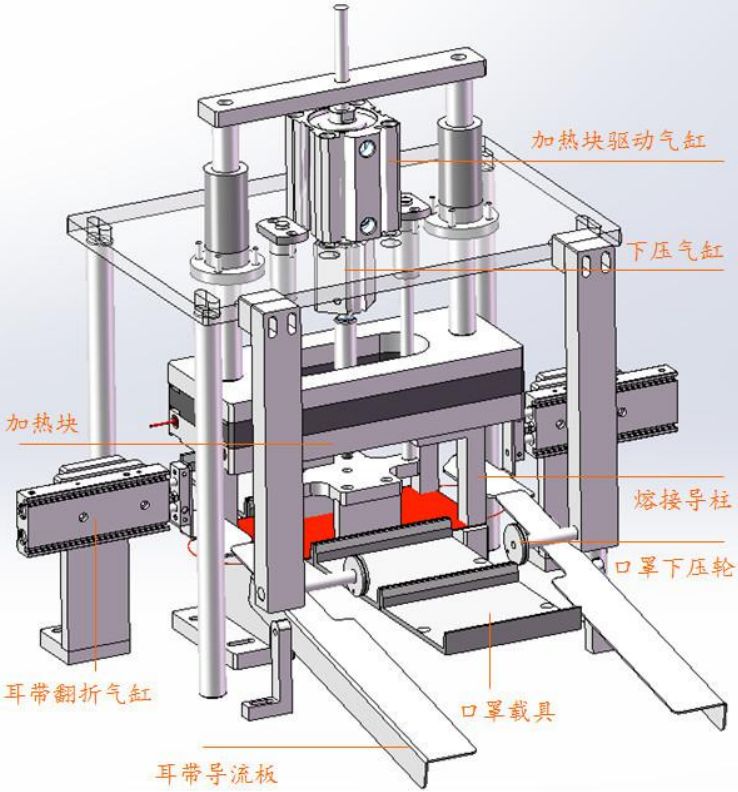

1) This mechanism is not complicated. The diagram above is basically marked clearly, so just talk about the sequence of actions:

→ The mask carrier conveys the mask. When passing the ear deflector, fold the ear band 90 °

To prevent masks from being brought up during diversion);

→ After reaching the position, press down on the cylinder to hold down the mask, and then turn the earpiece over to push the earpiece forward to

On the mask, return;

→ Press down the welding guide post, press the contact point between the earband and the mask body, and then heat it.

4, palletizing mechanism

1) Mechanism action sequence

→ The carrier conveys the mask to the belt line, and the conveyor belt brings the mask to the blanking place;

→ The upper sensor has a counting function. For every 10 accumulators, press down on the cylinder, press 10 masks onto the feeding conveyor, and remove the masks manually. The entire equipment production process is completed.