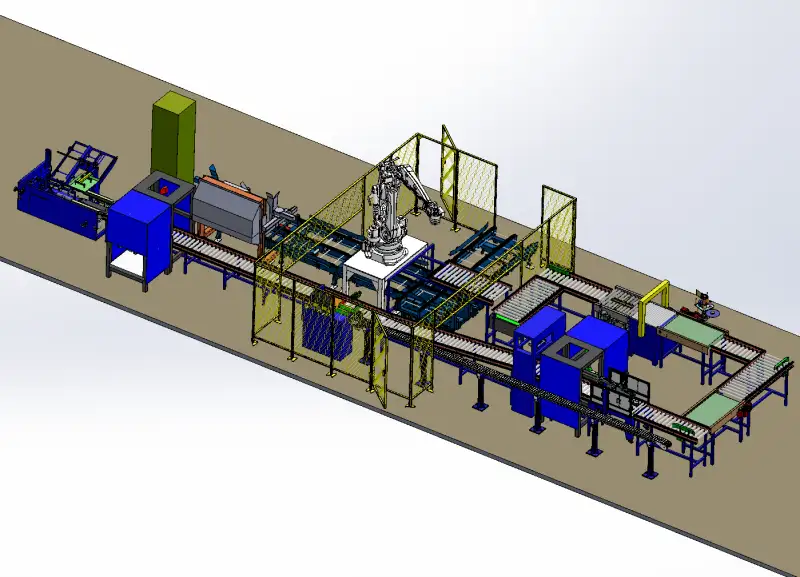

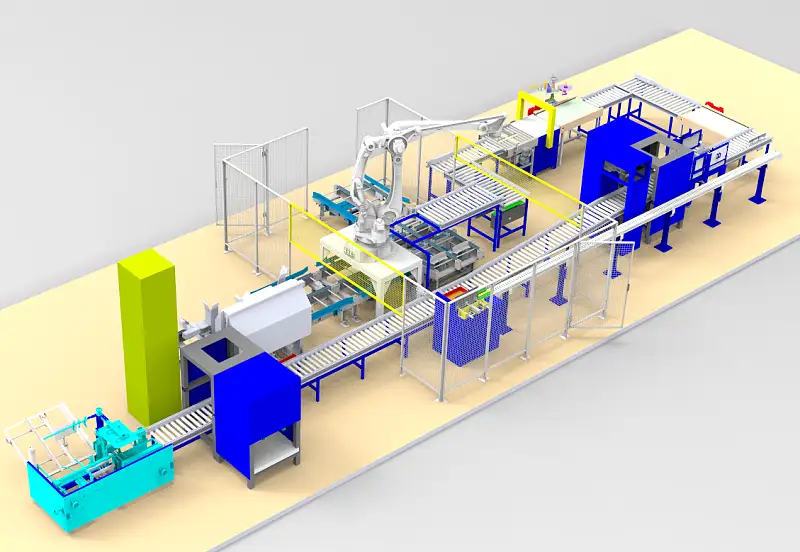

3D drawings of the post-packaging production line, the production line includes automatic tray unpacking and conveying system. Automatic carton unpacking, conveying, packing, labeling and palletizing system system. The robot uses Kawasaki CP180, and the robot performs packing and palletizing actions.

The design based on SolidWorks 2017, please use 2017 or above to open. The file is about 129 MB.

Post-packaging production line